In a factory, different machines perform different tasks they are specialized for in order to efficiently and effectively get the job done. In the same way, the workers will also perform different tasks they are specialized for to efficiently and effectively perform their own jobs. In this way, the factory can move like a well-oiled machine. To differentiate between a millwright and a mechanic, one can look at the jobs they perform.

Millwrights typically install, dismantle, and assemble heavy machinery. They are highly trained professionals who will move heavy-duty machinery toward the desired location within a factory. There, they’ll assemble it piece by piece using blueprints and complex knowledge of electronics and computers.

There is a great deal of skill and knowledge needed to be a millwright. They are expected to have at least a high school education, or even a degree from a technical college. They are expected to enter an apprenticeship program for 3-5 years. As millwright apprentices, they’ll gain job training including reading blueprints, diagnosing problems, as well as installing and dismantling equipment.

Often they might even be brought in for large-scale repairs of machinery. As they were involved in the installation and assemblage, they are familiar with the machine in a way that allows them to deal with major repair work. If the process requires it, they will disassemble and replace the old parts with newer parts, though in most cases such repair work can be left to the industrial mechanic.

An industrial mechanic, in contrast to a millwright, focuses on maintenance and repair. They ensure the heavy machinery that the millwright installed is maintained in its best condition. They’ll also repair the machine should it get damaged from wear and tear of daily use.

Industrial mechanics are expected to be incredibly familiar with the machines they maintain. They must be able to notice if small problems are present, for example, by keeping note of any vibrations within the machine. Through vibrations alone, they should be able dedicate if there is a problem present and the correct process to fixing that. By maintaining these machines, they prevent a small problem from developing into a much bigger issue that would require full-scale repair, or in some cases, replacement.

Much like a millwright, an industrial mechanic is expected to have at least a high school diploma or GED, with preference given to those who have gained formal education at a technical school. They are not expected to involve themselves in apprenticeships.

Their knowledge is oftentimes more specialized in certain fields, rather than focusing on a wider range of topics. However, in some cases, factories may ask their industrial mechanics to have at least some knowledge of other fields instead of specializing in just one.

For both the position of millwright and industrial mechanic, they are cases where you can find the title used interchangeably for each other. This occurs often because their duties can overlap. A millwright might be called in to repair a machine they assembled, just the same as a

mechanic.

However, the difference between these two stems from their focus. A millwright tends to have a much wider range of knowledge. A mechanic will focus on the specifics of maintenance and repair. Both are instrumental in ensuring a factory works efficiently,

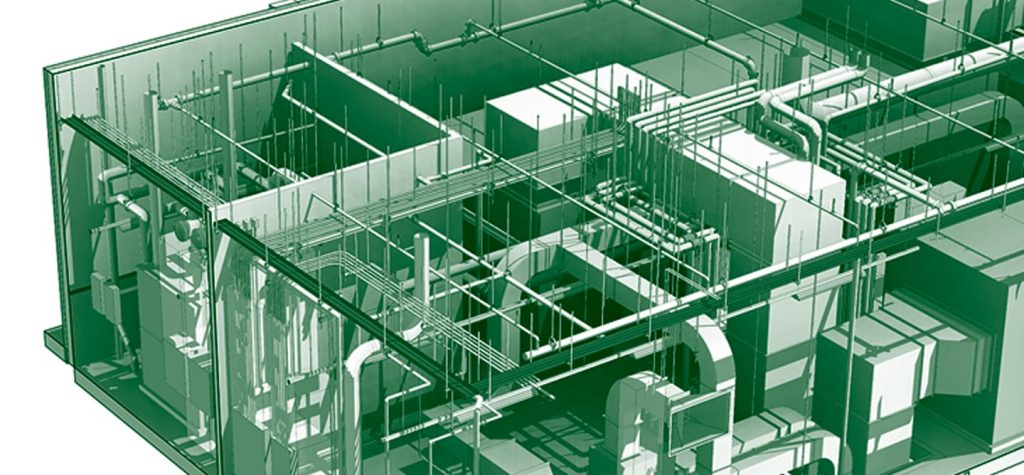

Since 1945, H.A. Sack has been the company to look to for high-quality construction service. H.A. Sack was built upon providing heavy commercial and industrial construction. We are able to perform many different steps of the construction process in-house, such as electrical, mechanical, piping, plumbing, HVAC, and more kinds of work.

By hiring H.A. Sack, you’ll have the advantage of a multi-craft contractor who can coordinate the entire project. We’re a company dedicated to handling all our projects with professionalism, safety consciousness, and attentiveness. For a millwright you can trust, contact H.A. Sack to discuss future projects.

We’re committed to hiring, training, growing and retaining the finest workforce in the industry. Join our growing team today.